Types of Tablet Counting Machines and Their Price Differences

Manual vs. Semi-Automatic vs. Fully Automatic Tablet Counting Machine

The cheapest option at first glance is manual tablet counters, which work great for tiny pharmacies or clinics that don't handle much volume day to day. These old school machines need someone standing there turning knobs and watching closely all the time, which means plenty of chances for counting errors when staff gets distracted. Then there are semi automatic versions that have some electronics built in along with simple automation features. They cut down on mistakes compared to purely manual ones and still won't break the bank, so they fit well in places with moderate prescription volumes. At the top end we find fully automatic systems. These bad boys come with expensive software packages, fancy sensors everywhere, and need special setup within existing production lines. But hey, if a pharmacy wants blister packs coming out fast and accurate every single time, this is what big manufacturers go for despite the hefty price tag.

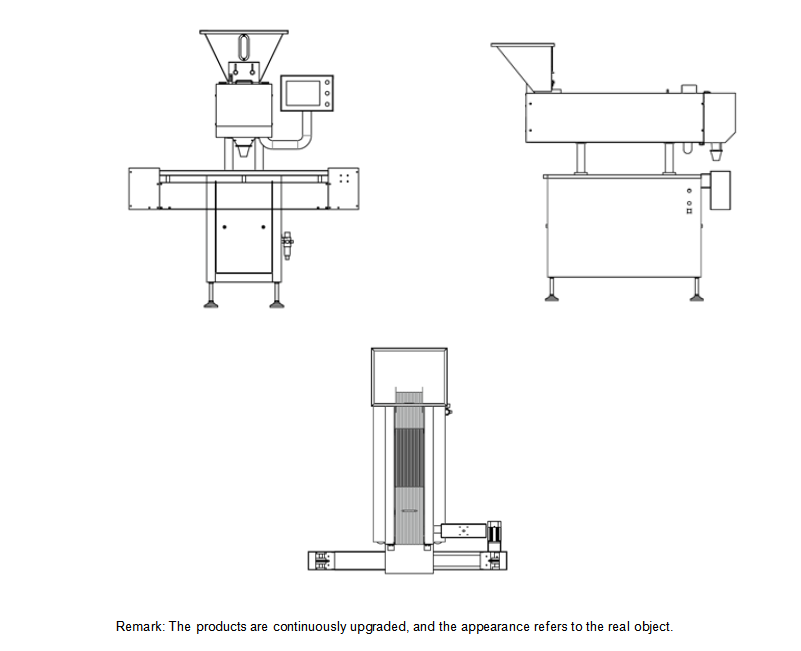

Portable and Bulk Models for Specialized Pharmaceutical Applications

The portable tablet counter gets around easily, which is why they work so well in places like hospital pharmacies, those pop-up clinics we see at community events, or even during emergency response situations in the field. These smaller machines cost roughly 15 to 30 percent less than their big brothers because they're made to be carried from place to place. When looking at the other end of the spectrum, bulk feed models take up serious space in factories and warehouses. They come equipped with heavy duty hoppers that can handle massive volumes, automatic sorting mechanisms, and all sorts of custom features depending on what kind of materials need processing. The price tag on these industrial beasts varies wildly though. A basic model might start at several thousand dollars, but when companies want something that lasts decades and integrates seamlessly into existing production lines, expect to pay much more.

High-Speed, Medium-Speed, and Low-Speed Machines: Performance vs. Cost

High-speed machines justify their premium through labor reduction and production scalability, while low-speed units remain essential for cost-sensitive environments with limited daily counts.

Key Specifications That Affect Tablet Counting Machine Pricing

How Automation Level Influences Machine Cost

How automated something is has a big impact on what it costs to make, mainly because of how complicated the parts get and what kind of manufacturing is needed. The most basic manual machines just need some simple mechanical components, so they usually cost between $1,500 and $3,000. When we move up to semi-automatic versions, things start getting pricier since they need electronic sensors and basic control systems built in, which brings the price tag up to around $5,000 to $15,000. Fully automatic systems are where the real money comes into play though. These high-end models come packed with advanced PLC controllers, touchscreens for operation, and all sorts of precision alignment tech, making them range from $20,000 right up past $50,000. The jump in price isn't just about materials and assembly though. Manufacturers know that investing in automation pays off over time too. Studies in the pharmaceutical industry show that these automated systems can cut down on counting labor by as much as 80 percent, which explains why many companies still see value despite the upfront investment.

Speed, Accuracy, and Capacity: Core Performance Metrics and Price Impact

High-speed models require precision motors and vibration dampeners, while pharmaceutical-grade accuracy relies on optical or electromagnetic counting technology. Larger capacities demand robust stainless-steel construction and structural reinforcement. Each 10% increase in throughput typically adds 7–12% to base pricing, based on industrial automation data.

Pill Size and Type Compatibility: Customization and Cost Implications

The price goes up when manufacturers need equipment that can handle all sorts of different tablet shapes and sizes. Basic machines made just for those standard round pills tend to be cheapest option available on market right now. When companies want machinery that works across various pill dimensions from about 2mm up to 25mm diameter, they have to get models with adjustable feed chutes plus sensors that need regular recalibrations. This usually adds around 15% to 20% extra cost compared to standard units. Things get even pricier for systems that work with soft gel caps, traditional capsules or oddly shaped tablets. Such setups typically come with special vibrating trays and built-in anti static components which push prices up between 25% and 40%. While these fancy features help avoid jams during operation and maintain counting accuracy, they definitely mean bigger upfront expenses for pharmaceutical businesses looking to upgrade their packaging lines.

Total Cost of Ownership for Tablet Counting Machines

Evaluating the true expense of tablet counting machines requires analyzing Total Cost of Ownership (TCO), not just purchase price. TCO includes upfront costs, ongoing operational expenses, and residual value over the machine’s lifespan.

Upfront Investment vs. Long-Term Labor and Operational Savings

Counters that are manually operated come with relatively low upfront costs, typically ranging from around $1,000 to $5,000. However, they end up costing much more in labor over time. Think about it this way: if a technician spends about 15 hours each week on counting tasks at $25 per hour, that adds up to nearly $20,000 a year just for labor alone. On the flip side, fully automatic systems might cost significantly more initially, often starting at around $20,000, but they cut down labor requirements by roughly 70%. These systems also help prevent costly mistakes. According to a study published by Ponemon in 2023, counting errors result in approximately $740,000 worth of wasted pharmaceutical products every year. To understand the real value proposition here, we can look at total cost of ownership using this basic formula: Total Cost of Ownership equals the initial investment plus annual operating costs multiplied by expected lifespan minus any residual value left at the end. Let's see how this works in practice.

- Automatic machine: $22,000 + ($2,500/year × 10 years) – $3,000 = $44,000

- Manual alternative: $3,000 + ($19,500/year × 10) – $300 = $195,300

Maintenance, Downtime, and Energy Efficiency in Automatic Systems

Premium automatic machines reduce long-term costs through enhanced reliability and efficiency:

- Preventive maintenance: Annual service contracts at $1,200 prevent downtime losses averaging $15,000 per hour

- Energy-smart designs: Consume 30% less power than older models

- Component durability: Laser sensors last over 5 years compared to 18 months in budget systems

One facility reported 98% uptime after switching to high-quality automatic counters, eliminating $28,000 in monthly lost orders. While these models carry a 20% higher initial price, their 5-year TCO averages 40% lower due to superior reliability and operational efficiency. Prioritizing TCO transforms tablet counting from a cost center into a strategic value driver.

FAQ Section

What is a tablet counting machine? A tablet counting machine is a device used to count and dispense tablets accurately, primarily used in pharmaceutical industries and pharmacies.

How does the level of automation affect the cost of a tablet counting machine? The level of automation affects the cost due to the complexity of parts and manufacturing required. Fully automated machines are more expensive due to advanced features but can reduce labor costs significantly.

What factors influence tablet counting machine pricing? Key factors influencing pricing include automation level, counting speed, accuracy, hopper capacity, type compatibility, and TCO (Total Cost of Ownership).

Why is Total Cost of Ownership important when evaluating tablet counting machines? TCO is important as it evaluates not only the purchase price but also ongoing operational costs and potential savings over the machine’s lifespan.