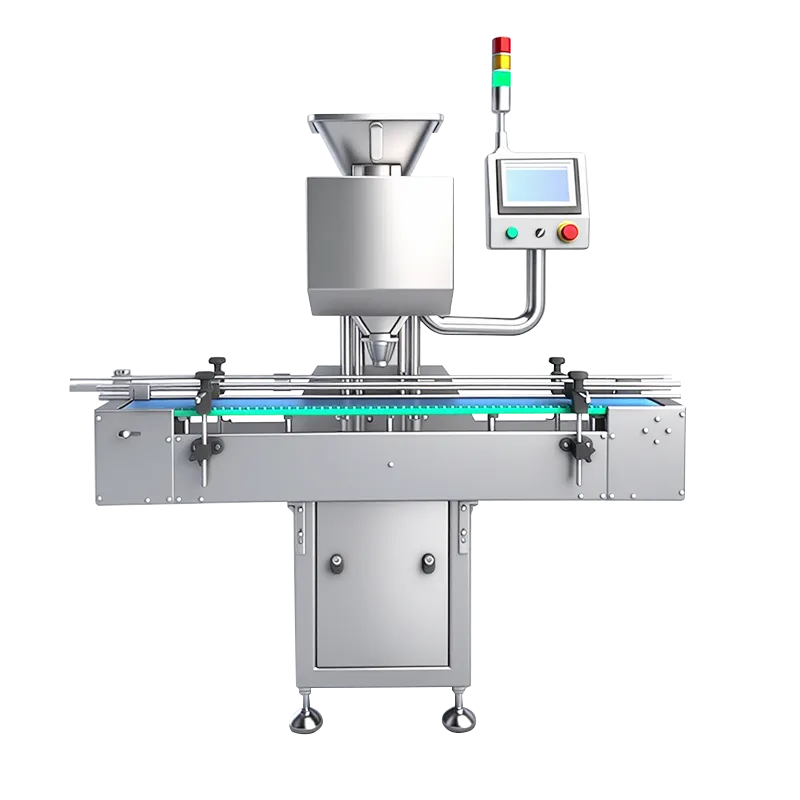

What Is an Automatic Counting Machine? Core Components and Functionality

Definition and Role of the Automatic Counting Machine in Food Production

Automatic counting machines, often called ACMs for short, are pretty much essential tools in food packaging lines these days. They basically count items as they move along conveyor belts, which cuts down on mistakes people make when doing it manually. This matters a lot because wrong labels or bad counts lead to most food recalls actually. Studies show around three out of four recalls happen for exactly these reasons. When companies automate counting instead of relying on workers, they get better control over how much goes into each package. Plus, there's less wasted product at the end of long shifts where tired hands might miscount again and again.

Key Components: Sensors, Conveyors, Control Systems, and Integration Points

Three core subsystems enable reliable operation:

- Multi-spectral sensors detect variations in product size, shape, and position at speeds up to 1,200 items/minute

- Programmable logic controllers (PLCs) adjust conveyor speeds and sorting mechanisms in real time

- Standardized integration ports allow seamless communication with upstream/downstream equipment like checkweighers and labeling machines

How Machine Vision Enables High-Precision Food Item Enumeration

Today's automated counting machines rely on advanced computer vision tech to tally all sorts of odd-shaped goods such as chips or frozen peas. The systems have smart lights that adjust automatically when dealing with shiny surfaces, and they employ three dimensional sensing technology which can tell apart stacked products with almost perfect precision around 99.9 percent accurate most of the time. These improvements really cut down on errors that plague older methods based purely on weight measurements. Especially problematic for things like breaded chicken pieces or fresh produce where water content changes throughout processing, leading to inconsistent readings on scales.

Why Accurate Counting Matters: Preventing Waste, Ensuring Compliance, and Protecting Brand Trust

Risks of Inaccurate Counts: Product Recalls, Consumer Dissatisfaction, and Financial Loss

When food packaging has wrong counts, companies face both money problems and legal trouble right away. According to some industry numbers from last year, smaller to medium sized food makers are losing around seven hundred forty thousand dollars every year because of simple counting mistakes. And guess what? About two thirds of all compliance issues come from packages having too little product inside. These shortages create inventory headaches throughout the whole supply chain and customers end up asking for refunds all the time. The real big problem though happens when quantity labels are just plain wrong. This breaks FDA rules and forces companies into expensive recalls. Take one snack company as an example they lost nearly 2.3 million bucks when their packages had less product than labeled, which violated those nutrition labeling laws. Worst part? People stopped trusting them completely for almost a full year and a half after everything came out.

Meeting Food Safety Regulations and Packaging Standards with Automated Accuracy

Automatic counting machines help keep food producers compliant with those tough safety regulations, especially since the FDA wants at least 99.5% of all packages to match what's printed on them. When it comes to getting portions right, these systems really cut down on mistakes people make manually, which matters a lot when dealing with allergens and making sure nutrition info is accurate. The best part? These counting systems work hand in hand with checkweighers and vision inspection tech so they can spot packages that are short on product or look off somehow as soon as they come off the line. That means fewer bad batches end up at stores. And let's face it, nobody wants to pay around $220k every time there's a labeling issue. Those fines only get worse if problems keep happening again and again.

Case Study: Snack Food Recall Due to Counting Errors and Its Operational Impact

A major snack company had to pull back nearly half a million pretzel bags from shelves in 2022 when their manual counting process failed spectacularly. About 15% of those packages ended up shortchanged, which means customers got less product for their money. The fallout was severe financially too, running them close to $1.8 million straight out of pocket while losing almost a quarter of their market position in just half a year. After licking their wounds from this mess, they decided enough was enough and invested in automatic counting systems for their packaging lines. These new machines brought their count accuracy up to an impressive 99.98%. Not only did this fix the obvious problem, but it also slashed packaging waste by around 18% and trimmed labor costs down by 40%. The investment paid itself back completely within 11 months thanks to both avoiding regulatory fines and slowly winning back customer trust over time.

Integration into Automated Production Lines for Real-Time Quality Assurance

Synchronizing Automatic Counting Machines with Filling, Sealing, and Packaging Systems

When automatic counting machines work together properly with the rest of the packaging line including fillers, sealers, and carton packagers, they run at their best. Most modern systems communicate using standard protocols like OPC-UA so all the equipment can talk to each other smoothly. Imagine what happens when a sensor spots something missing from the count it's supposed to make. The whole packaging process just stops right there until someone fixes whatever went wrong. This kind of connection between different parts of the line helps prevent those annoying product jams that slow things down, and also keeps customers from getting packages that don't have enough items inside them.

Real-Time Data Feedback for Immediate Error Detection and Process Correction

Today's counting systems track real time performance data using those smart IoT sensors, catching problems such as extra counts or items that get off track pretty fast, usually under half a second. When something goes wrong, operators get warnings right away on their dashboard screens. They can then tweak how fast the conveyor belts run or fix sensor settings all without having to shut down the whole line. A company making baked goods saw this work wonders for them last year. Their waste from counting errors dropped around 18 percent in 2023, and they kept almost perfect accuracy rates throughout their shifts, hitting close to 99.97% most of the time.

Industry Example: Bottled Beverage Line with Integrated Counting and Verification

One major European drinks manufacturer got rid of all those tedious manual checks on product cases by connecting their automatic counting equipment directly to the palletizing robots they already had running. Before boxes go into the shrink wrap tunnels, smart vision systems count each bottle individually. At the same time, weight sensors double check if everything adds up correctly compared to what should be there according to their set standards. This two pronged approach ended up catching over 12 thousand counting mistakes every year, which saved the company around four hundred twenty thousand dollars worth of possible recalls down the road. Plus, the whole setup automatically creates all the necessary documentation needed for those tricky FDA 21 CFR Part 11 inspections without anyone having to lift a finger.

Operational ROI: Reducing Downtime, Labor Costs, and Human Error

Facilities that have switched to integrated counting systems see their line changeovers speed up by around 35% when compared with old fashioned manual counting methods. The reason? These systems automatically tweak machine settings based on whatever package format is needed next. Many manufacturers are finding they can do away with 3 to 5 manual quality control checkpoints along each production line. This saves them anywhere from seventy four thousand to one hundred twenty thousand dollars every year just on labor expenses alone. Plus it gets rid of those annoying counting mistakes people make after working long shifts. And there's another benefit too. Predictive maintenance software helps factories avoid unexpected shutdowns by keeping an eye on things like how motors vibrate or when optical sensors start showing signs of wear and tear.

The Role of Machine Vision and AI in Advancing Automatic Counting Technology

AI-Powered Image Recognition for Distinguishing Similar or Variably Shaped Food Items

Today's automatic counting machines rely on machine vision systems powered by artificial intelligence to spot food items that are oddly shaped or stuck together, like mixed nuts or those freeze dried fruit snacks we all love. The tech looks at detailed images and uses pattern recognition software that has been trained on literally thousands of different products. When almonds and cashews get all tangled up during bulk processing, these smart vision sensors can tell them apart based on their shape and surface feel. According to research from last year, factories using AI for counting saw a massive drop in mistakes - around 96% fewer errors than older optical sensor methods when dealing with nuts specifically.

Deep Learning Models That Improve Counting Accuracy Through Continuous Training

Traditional rule based systems just cant keep up when products change shape or packaging gets updated. Deep learning changes all that by letting counting machines adjust on their own without anyone having to rewrite code every time something new shows up on the production line. These systems actually learn from what happens day to day on factory floors. They get better at tricky tasks like spotting broken potato chips mixed into good ones or finding those pesky missing tablets in blister packs. Food manufacturers who have implemented these smart models see around 15 to maybe even 30 percent fewer errors each year. That means safer products for consumers and less hassle meeting those strict FDA and European Union regulations about food safety.

Edge Computing: Enabling Faster, On-Site Decision-Making in Automatic Counting Machines

When edge AI processors are built right into counting equipment, they enable quick quality assessments without waiting on slow cloud connections. This matters a lot on fast production lines that churn out over 800 products every single minute. The local processing power can actually count fragile goods such as flaky croissants from bakeries or mixed loose leaf teas within just 50 milliseconds flat. According to Food Engineering from last year, this cuts down conveyor belt stops by around 40 percent. Plus, since these edge systems don't send data outside the facility, they naturally boost security against cyber threats for important manufacturing logs and records.

Measuring Performance and ROI: KPIs and Long-Term Value of Automatic Counting Machines

Key Performance Indicators: Count Accuracy Rate, Throughput, and Error Detection Speed

Modern automatic counting machines achieve ≥99.95% accuracy across food items like snacks, frozen produce, and pharmaceutical-grade ingredients. Three metrics dominate performance evaluation:

- Count Accuracy Rate: Gap analysis between machine-reported and manual audit counts (industry target: ≤0.03% variance)

- Throughput: Typical systems handle 1,200–2,500 units/minute, exceeding manual counting by 15x (Ponemon 2023)

- Error Detection Speed: Advanced models identify miscounts within 0.8 seconds, preventing ≤92% of defective batches from advancing

Calculating Return on Investment Through Waste Reduction and Labor Efficiency

A $540k automatic counting machine installation for nut packaging demonstrates ROI potential:

| Cost Factor | Manual Process | Automated System |

|---|---|---|

| Labor Hours/Shift | 18 | 3 |

| Product Waste Rate | 2.4% | 0.7% |

| FDA Compliance Fines | $27k/year | $1.2k/year |

These improvements, combined with 98.6% fewer customer complaints about underfilled packages, typically deliver full ROI within 2.5–3 years. Industry automation guidelines recommend tracking both direct savings and risk mitigation benefits.

Balancing Maintenance, Upgrade Costs, and Long-Term Operational Gains

While premium systems require $18k–$35k annually in maintenance contracts, operators report:

- 43% fewer unplanned downtime events vs manual QA processes

- 22% longer mean time between failures (MTBF) when using OEM parts

- 7:1 cost advantage in lifecycle upgrades over system replacement

This cost-benefit profile makes automatic counting machines a strategic investment rather than a tactical expense, particularly for food manufacturers targeting ISO 22000 certification.

FAQs

What is an automatic counting machine?

An automatic counting machine is a device used in food packaging lines to count items moving along conveyor belts, reducing errors associated with manual counting.

Why is accurate counting important in food production?

Accurate counting prevents product waste, ensures regulatory compliance, and maintains customer trust by reducing recalls and dissatisfaction caused by incorrect package contents.

How does automatic counting technology improve compliance?

Automatic counting machines ensure package contents match printed labels, working with checkweighers and vision technology to meet FDA requirements and avoid labeling issues.

What role do machine vision and AI play in these machines?

Machine vision and AI help in identifying and counting variably shaped items, enhancing accuracy and efficiency by learning from everyday operations on production lines.

How is ROI measured for automatic counting machines?

ROI is measured through improvements in labor efficiency, waste reduction, reduced compliance fines, and operational cost savings, typically achieving full ROI within 2.5–3 years.

Table of Contents

- What Is an Automatic Counting Machine? Core Components and Functionality

- Why Accurate Counting Matters: Preventing Waste, Ensuring Compliance, and Protecting Brand Trust

-

Integration into Automated Production Lines for Real-Time Quality Assurance

- Synchronizing Automatic Counting Machines with Filling, Sealing, and Packaging Systems

- Real-Time Data Feedback for Immediate Error Detection and Process Correction

- Industry Example: Bottled Beverage Line with Integrated Counting and Verification

- Operational ROI: Reducing Downtime, Labor Costs, and Human Error

- The Role of Machine Vision and AI in Advancing Automatic Counting Technology

- Measuring Performance and ROI: KPIs and Long-Term Value of Automatic Counting Machines

- FAQs