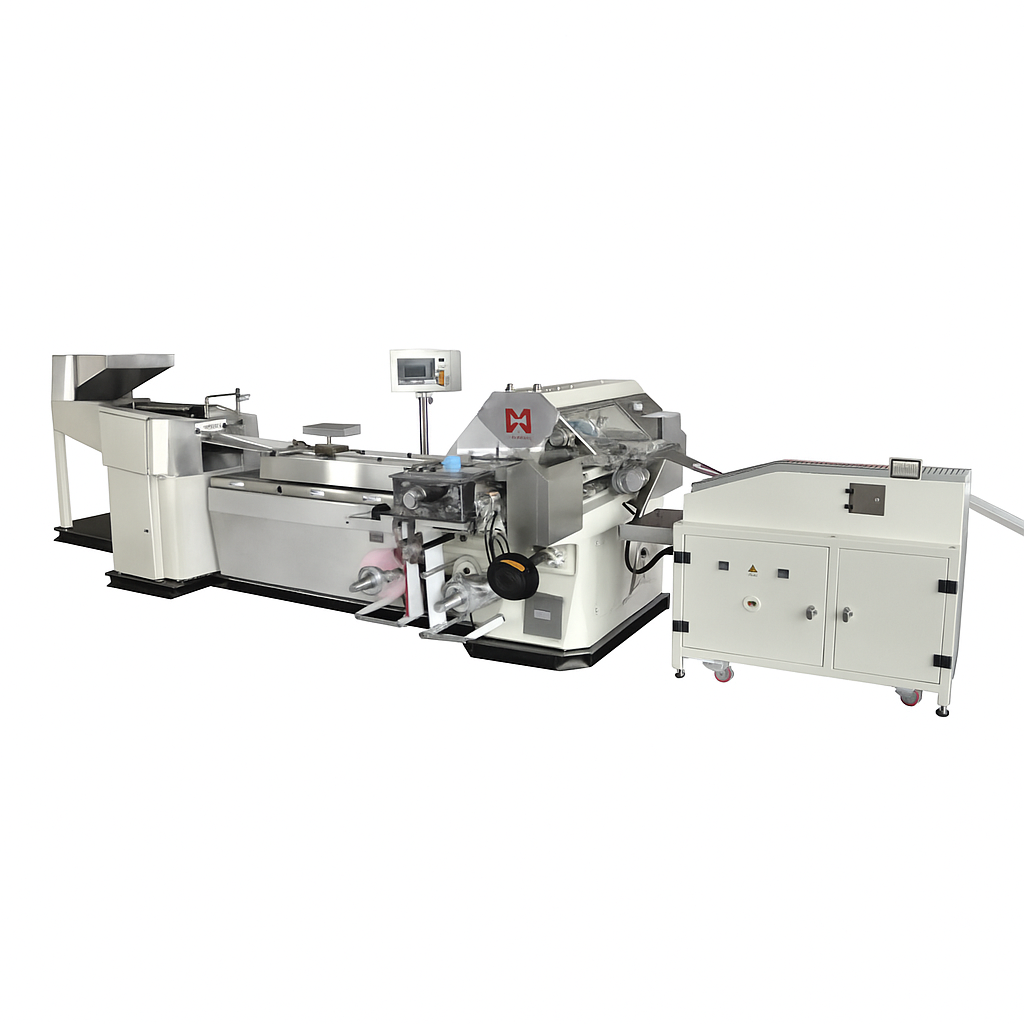

1. Inverter speed control

2. Automatic control of photoelectric scanning detection

3. Automatic fault alarm system: display fault information and reason, automatically stop the machine

4. Automatic feeding system including tablets feeding, paper feeding, tube feeding, etc. Packing speed can reach 80-100 tubes per minute.