Why Choose the Automatic Blister Packaging Line for Pharmaceuticals?

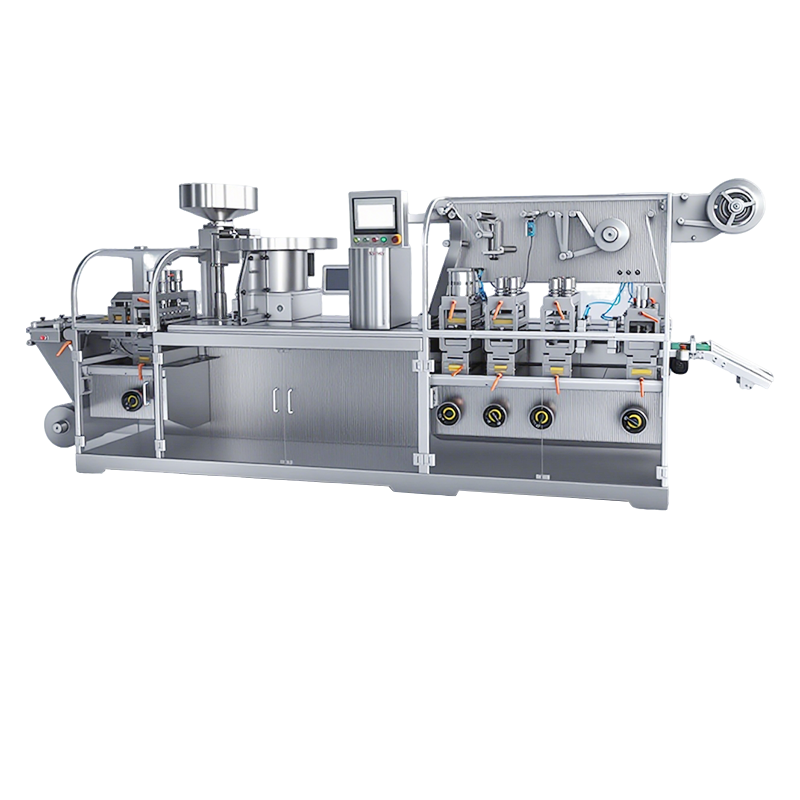

In the fast-paced world of pharmaceutical production, ensuring efficiency, accuracy, and compliance is critical. The Automatic Blister Packaging Line for Pharmaceuticals is designed to meet the demands of modern pharmaceutical manufacturing, providing a seamless, high-quality solution for packaging tablets, capsules, and other medical products. With state-of-the-art automation, GMP compliance, and cutting-edge technology, our system guarantees not only peak performance but also utmost reliability in every batch.

As the pharmaceutical industry continues to evolve, manufacturers are increasingly turning to advanced automation to meet higher production demands while maintaining the highest standards of quality and safety. The Automatic Blister Packaging Line is engineered specifically to streamline your packaging process, reducing manual intervention, improving efficiency, and ensuring that your products are perfectly sealed, protected, and traceable. Whether you're packaging tablets, capsules, or soft gels, our system is the most reliable, versatile, and cost-effective solution on the market.

Main Features and Advantages of Automatic blister packaging line

1. Fully Automated Production:

Our Automatic Blister Packaging Line takes automation to the next level. From forming and filling to sealing and cutting, every stage is automated, significantly reducing the need for manual labor and minimizing human error. This results in faster production cycles and lower operational costs.

2. GMP and FDA Compliance:

Compliance with Good Manufacturing Practices (GMP) and FDA regulations is essential in pharmaceutical packaging. Our machine is fully certified, ensuring that your products meet the strictest safety and quality standards required by the industry. With our system, you can rest assured that your packaging process is fully compliant with regulatory requirements.

3. High-Speed, High-Volume Production:

Designed for large-scale production, the Automatic Blister Packaging Line operates at high speeds without compromising quality. It’s capable of packaging large volumes of pharmaceutical products efficiently, making it ideal for companies looking to scale their operations while maintaining exceptional product quality.

4. Precision and Reliability:

The precision engineering behind this blister packaging line ensures that every blister pack is perfectly formed, sealed, and ready for distribution. This reduces the risk of packaging defects and product contamination, ensuring that your customers receive products that meet the highest quality standards.

5. Customizable for Various Packaging Needs:

Our system is highly customizable, catering to a wide range of pharmaceutical products, including tablets, capsules, and soft gels. Whether you’re packaging a small batch of specialized products or large quantities for mass distribution, our system adapts to your needs.

6. Energy-Efficient Design:

We understand the importance of reducing operational costs, and that’s why our Automatic Blister Packaging Line is designed to be energy-efficient. The optimized design ensures that energy consumption is minimized, reducing your overall production costs.

7. Easy-to-Operate Interface:

Despite its sophisticated technology, the system is incredibly user-friendly. Operators can easily set parameters, monitor the packaging process, and adjust settings through an intuitive touchscreen interface, reducing the training time and improving workflow.

Application of Automatic blister packaging line

Ideal for Pharmaceutical Manufacturers of All Sizes

Whether you’re a small, specialized manufacturer or a large-scale production facility, our Automatic Blister Packaging Line offers scalable solutions that grow with your business. It’s the perfect choice for any pharmaceutical manufacturer looking to automate their packaging process, ensure regulatory compliance, and improve efficiency.

Perfect for:

-

Tablets and capsules

-

Soft gels

-

Medical devices

-

Nutraceuticals

-

Over-the-counter medications

-

Prescription medications

why choose us

As a leading supplier of blister packaging machinery, we provide not only the most advanced, automated systems but also the unparalleled support you need. Our team of engineers works closely with you to ensure that the Automatic Blister Packaging Line integrates seamlessly into your existing production process, helping you achieve maximum productivity with minimum downtime.

Frequently Asked Questions

1: What is an Automatic Blister Packaging Line for Pharmaceuticals?

Answer:

An Automatic Blister Packaging Line for Pharmaceuticals is a fully automated system used to package pharmaceutical products such as tablets, capsules, and soft gels. It involves the automated processes of forming, filling, sealing, and cutting blister packs, ensuring high efficiency, consistency, and compliance with industry standards. This type of line significantly reduces manual labor and increases production speed, making it ideal for large-scale pharmaceutical manufacturers.

2: Is the Automatic Blister Packaging Line GMP Compliant?

Answer:

Yes, our Automatic Blister Packaging Line is fully GMP (Good Manufacturing Practices) compliant. It is designed to meet the strict quality and safety standards required by the pharmaceutical industry. With GMP certification, you can be confident that your packaging process adheres to the highest regulatory guidelines, ensuring both product integrity and consumer safety.

3: What Types of Pharmaceutical Products Can the Packaging Line Handle?

Answer:

The Automatic Blister Packaging Line is highly versatile and can handle a wide range of pharmaceutical products, including:

-

Tablets

-

Capsules

-

Soft gels

-

Pills

-

Nutraceuticals

-

Over-the-counter (OTC) medications

-

Prescription medications

The system is designed to accommodate various blister formats, including PVC, ALU, and combination materials, allowing flexibility for different product types and packaging requirements.

4: What is the Production Speed of the Automatic Blister Packaging Line?

Answer:

The production speed of our Automatic Blister Packaging Line is highly efficient, capable of processing up to 150-300 blisters per minute, depending on the product type and packaging specifications. This high-speed operation ensures that your manufacturing process meets large-scale production demands without compromising on quality or precision.

5: Can the Automatic Blister Packaging Line Be Integrated into an Existing Production Line?

Answer:

Yes, the Automatic Blister Packaging Line is designed to be easily integrated into your existing production process. Our team of engineers will work with you to ensure a smooth installation and setup, whether you’re expanding your existing capacity or upgrading your current system. The line is highly customizable and can be adapted to fit your specific production needs, maximizing efficiency and reducing downtime during transitions.

6: How much does an automatic blister packaging line for pharmaceuticals cost?

Answer:

The cost of an Automatic Blister Packaging Line for Pharmaceuticals depends on several factors, including production speed, customization, and additional features. Typically, pricing will vary based on your specific packaging needs, including the type of product you are packaging and the materials used. For an accurate quote, it is best to contact our sales team to discuss your requirements and receive a tailored price estimate.

7:How easy is it to operate the automatic blister packaging line?

Answer:

The Automatic Blister Packaging Line is designed for ease of use with an intuitive interface. Operators can quickly learn to control the system, adjust settings, and monitor the packaging process via a user-friendly touchscreen. Its automated functions minimize the risk of operator error, and training time is significantly reduced.

8:What are the maintenance and service requirements for the automatic blister packaging line?

Answer:

The Automatic Blister Packaging Line requires minimal maintenance. Routine inspections, cleaning, and lubrication of moving parts are recommended to keep the system running smoothly. Our team provides comprehensive after-sales support, including maintenance, spare parts, and remote diagnostics to ensure continuous uptime and optimal performance.

9:What are the packaging materials compatible with the automatic blister packaging line?

Answer:

The Automatic Blister Packaging Line is compatible with various packaging materials, including:

-

PVC (Polyvinyl Chloride)

-

ALU (Aluminum)

-

ALU-PVC (Aluminum-PVC) combination materials

This flexibility allows you to package different types of pharmaceutical products, ensuring that they are properly protected, sealed, and shelf-stable.

10:How long is the warranty for the automatic blister packaging line?

Answer:

The Automatic Blister Packaging Line comes with a standard warranty, typically lasting 1-2 years from the date of installation. This warranty covers any defects in materials or workmanship. Extended service plans are also available, which include regular maintenance, training, and remote support to ensure long-term performance.

Table of Contents

- Why Choose the Automatic Blister Packaging Line for Pharmaceuticals?

-

Main Features and Advantages of Automatic blister packaging line

- Application of Automatic blister packaging line

- 1: What is an Automatic Blister Packaging Line for Pharmaceuticals?

- 2: Is the Automatic Blister Packaging Line GMP Compliant?

- 3: What Types of Pharmaceutical Products Can the Packaging Line Handle?

- 4: What is the Production Speed of the Automatic Blister Packaging Line?

- 5: Can the Automatic Blister Packaging Line Be Integrated into an Existing Production Line?

- 6: How much does an automatic blister packaging line for pharmaceuticals cost?

- 7:How easy is it to operate the automatic blister packaging line?

- 8:What are the maintenance and service requirements for the automatic blister packaging line?

- 9:What are the packaging materials compatible with the automatic blister packaging line?