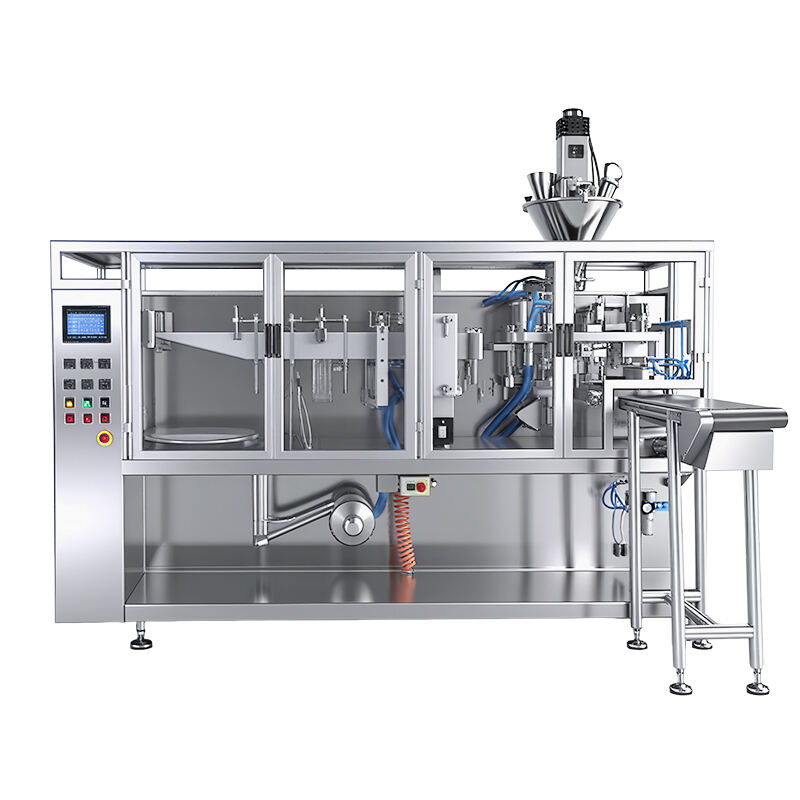

1. Automatic Feeding: The machine automatically picks up pre-made bags and ensures correct placement for seamless operation.

2. Precise Material Measurement: Equipped with a pressure sensor system, it ensures accurate filling and precise material measurement, reducing waste and ensuring consistency.

3. Secure Sealing: The machine automatically seals each bag, ensuring a reliable, high-quality seal that prevents leakage and contamination.

4. High-Speed Output: The sealed bags are efficiently transferred to the output area via a conveyor belt, enhancing productivity and reducing labor costs.

5. Durable and Easy to Maintain: Built with high-quality stainless steel components, the machine is designed for long-lasting performance and minimal maintenance.